Hello ,

We are trying to customise tryton for a client.

The factory receives machinery parts from their clients for performing a series of chemical cleaning and anti rust coating. After the process the parts are returned back to the client and an invoice for this service is raised.

Also factory uses chemicals as consumables for the above process. We plan to process the consumables through the normal purchase module.

However since this will be our first deployment, we are yet unclear how to handle for purposes of record and inventory keeping, invoicing for services rendered on the machinery parts received from our clients.

We cannot handle them through the standard purchase modules as we do not need invoice to be generated while the product is coming in.

Any guidance on the topic would be much appreciated.

Thank you in advance.

We have not yet a module to manage such service works. Add module to allow services to be invoiced when they are done (#9999) · Issues · Tryton / Tryton · GitLab should be a good starting point.

Usually consumable are not really managed. You just purchase at a specific frequency.

I do not understand why you would like to manage the services with the purchase.

Indeed you are just selling services which are invoiced I guess when it is done.

If you want to keep tracks of each operation performed, you will need the above mentioned concept and probably extended it to include the extra information you want to collect.

Thanks for the quick reply,

Actually the process flow is like this

On any given day lets say Day T

Parts flow inward :

Client X - Parts X1 - Quantity 20000

- Part X2 - Quantity 35000

- Part X3 - Quantity 15000

Client Y - Part Y1 - Quantity 10000

- Part Y2 - Quantity 1200

- Part Y3 - Quantity 7000

- Part Y4 - Quantity 300

Client Z …

Services performed on Day T+1, T+2,

Then on Day T+3

Parts flow outward :

Client X - Parts X1 - Quantity 2000

- Part X2 - Quantity 3000

- Part X3 - Quantity 10000

Client Y - Part Y1 - Quantity 10000

- Part Y2 - Quantity 1200

- Part Y3 - Quantity 5000

- Part Y4 - Quantity 30

Client Z … And then generate Invoices for these services.

Rest of the quantities may be processed and dispatched on some other days either completely or partially.

So now the trouble is to keep inventory of flow of parts and the services performed , based on a standard inward stock flow number. Also we need to record the amount of consumables used and for which batch of process.

This is the reason why we are trying to use Tryton to solve this problem.

I completely understand there may not be any module to perform this process, but just need a starting point to make one .

I have been handling this for years with a custom modules for a client (cleaning and coating of several industrial products).

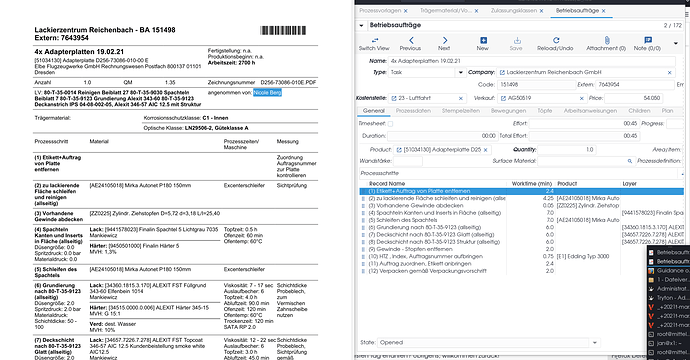

We are using the normal workflow of stock modules. Customer parts arrive in the warehouse and are proceeded into production departments, finally they leave back to the customer. The Service itself is handle with the project module on which the consumed material is booked (stock moves), timestamps are set and several process measures are collected.

The business workflow:

Request from customer generates a sale (eg coating of 1000 pieces).

Then from this sale you can start a project.

After finishing the project and delivery of the parts the invoice is generated.

Additional components are:

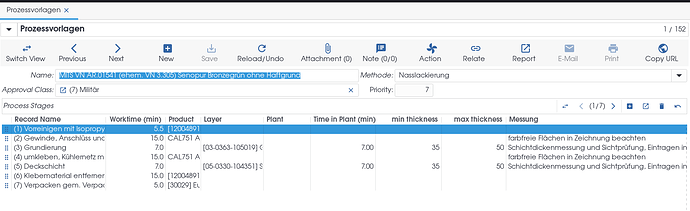

Processing templates (a model which holds all steps to do for coating)

This template can be linked to a product, if this is a long running contract or choosen on a particular project

In the background there is a lot of functionality to check contstraint bases on approval classes, the material of the incoming product and definitions regarding the process quality.

Here is an example of the output of the extended project module: lefts side a document handed out to the workers - right the form in tryton

Basically my client is probably doing the same business in germany as your customer does.

We have been working together for 10 years on this project. Today my customer is certified to work for the aviation industry and automotive industry using their ERP. With Airbus and MAHLE there is an EDI established.

Lets get in contact if you are interested.

I guess this is not manage by stock move? Because stock moves are for product owned by the company.

I’m not sure if the project is the right model to use because it is not linked to the original sale. That’s why I said that the Add module to allow services to be invoiced when they are done (#9999) · Issues · Tryton / Tryton · GitLab should probably by used.

Managing customer property is an essential requirement of quality management. Customer property is to be treated like company property in this sense. At the end of the year, these parts are also counted and the inventory reported to our customers. For this reason, in addition to warehouses for goods, there are also various warehouses for customer parts. So we are using stock moves (with some extension to mark them as customer goods)

I started 10 years ago - project was a good starting point since it allows some functionality to allocate resources or planning dates. I have it linked to sales and there is a wizard to generate project from sale. A lot of information is collected on sale before confirming which we pass over to the project. Will read your proposal. In our case, the core module has been expanded so much that it is actually only a minimal basis. Of course, this could also be tied to another model.

And we do not purchase them - only a shipment in is done which is linked to a sale. We have some functionality to encode the shipment from sale depending on conditions.

I do not think it is the right way to reuse stock move to manage in/out of material from customer.

Indeed as they will never be stored in the same place as goods and assets, I see no benefit to mix their concept together. Also the requirement of for tracking is probably lower than what you need for goods.

Here you are wrong in our case - the requirement on tracking parts in aviation is much, much higher than in most goods. We need to track them by part number and with a lot of papers.

And it is not “material” from the customer, it is goods that are refined. The process is very the same than for every other goods - there are delivery notes, shipments, internal moves, lot numbers and so on.

And also they are placed on every location of the company - in location, production, quality management, out location.

Possibly there could be a custom module for this use case. I decided to use the stock module with extensions and it works in daily business. Since we need all the functions of the stock module, I don’t see the advantage of almost identical new modules. Simple extensions to improve handling and clarity should suffice.

Thank you for your detailed reply, it looks like this is exactly what we were looking to establish.

As this will be our first project deployment we are still getting the hang of it.

Your project looks quite impressive, and we would be glad to connect.

If it is possible for you can we connect via email on amitabh.babar@gmail.com

If you are more comfortable with any other way of communication , let us know the same.