I can try.

Thanks @nicoe, here you go then…

I’ve just been having a look at the inventories and the inventory counting wizard, and I think I can see how it all works (please correct me if I am wrong).

The first part of this post tries to answer @coogor’s question and provide some examples of what I think the idea is behind the inventory counting wizard, and how it fits in with the inventories.

For my thoughts and suggestions (@nicoe and others) just skip to the “TL;DR - Some Notes” below.

Starting the Inventory

Normally you would create a new inventory, and fill in the location that the inventory is for. Next you would then press the “Complete” button to add the lines, and quantities, that the system thinks are currently in stock.

At this point you could just fill in the the quantities that have been counted into the “Quantity” column, this is easy if there are only a few lines.

The stock counting wizard is for the times where there are a lot of lines.

Stock Count Example

Lets say you have gone round the store room (which is a bit of a mess) counting all the items in the order they were stored on the shelves, and the stock count that was written down looked something like this:

Stock Count

-----------

Product 73: 10

Product 21: 5

Product 44: 2

... (many other items)

Product 21: 8

... (some more items)

You could use the stock counting wizard to enter these in. You would start the wizard using the “Count” button, then:

- Enter in the product from the stock count (the first one on the stock count would be Product 73) into the “Search” field, and press the “Select” button.

- Enter in the quantity that was counted into the “Added Quantity” (for the first item on the count this would be 10).

- Repeat this process, going down the hand written stock count, for each of the items.

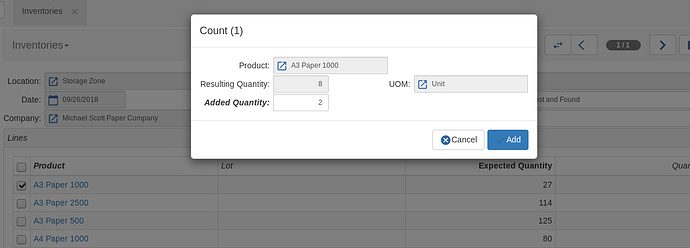

As you might have noticed “Product 21” appears on the stock count twice. The first time it is encountered when 5 is entered in as the “Added Quantity” the “Resulting Quantity” will also show 5. The next time it is encountered, and 8 is entered into the “Added Quantity” the “Resulting Quantity” will show 13. Once the inventory counting wizard has ended, the final inventory line for this product would show a “Quantity” of 13 (the 5 + 8 that were found in the two different places).

Zero Count Example

You are zero counting bins, and have gone and looked in the location that you are doing the inventory for. You have a list that looks like this:

Empty Bins

----------

Product 88

Product 17

Product 11

In this example let’s assume that you have created the inventory for the location and it contains hundreds of lines, so rather than manually searching through the list of lines, you decide to use the inventory counting wizard. So start the wizard and:

- Enter in the product from the list (the first one on the stock count would be Product 88) into the “Search” field, and press the “Select” button.

- Enter in 0 to the “Added Quantity” field.

- Repeat this process for each of the items on the list.

Confirming the Inventory

The inventory is confirmed once all the counts that are being done have been filled in.

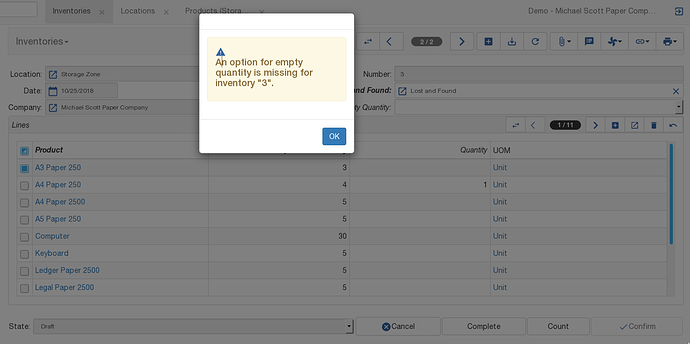

If there are any Inventory Lines that do not have a quantity filled in then the “Empty Quantity” field must be filled in, this is so the system knows what to do with these lines. In the “Empty Quantity” field select one of:

- Empty - Meaning: lines with a blank quantity indicate that none of the product was found and so its quantity should therefore be reduced to zero.

- Keep - Meaning: No change should be made to the stock level of the lines that have a blank quantity (these lines were simply not counted or looked at).

Note: @coogor, this is where you are encountering the An option for empty quantity is missing for inventory "3". error message. It is trying to tell you that for the inventory with 3 in the “Number” field the “Empty Quantity” field needs filling in with one of the two options (“Empty” or “Keep”).

TL;DR - Some Notes

Note: I can provide a patch for the below suggestions if you think that would be easier to see and review them there instead.

I have noticed that often when people are first using Tryton, and are trying to find out how much stock there is, they will commonly look in “Inventories” first. This is because inventory can mean the entire stock of a business, including materials, components, work in progress, and finished product (especially in accounting). Also the name of the “Locations” menu item does not give them any indication that they can find the stock levels by opening it. Renaming “Inventories” to “Stock Counts” may be something to consider, along with renaming the top most “Locations” menu item (although at the moment I’m not sure what you could rename it to).

Based on my understanding (in the examples above) of how the inventories work, there are some field and button names that I find slightly misleading.

-

Inventories:

- Field “Empty Quantity” → This sounds a bit like an action, a bit like it might empty the quantity. Perhaps, “Missing Quantities” or “Omitted Quantities” with options of “Reduce Stock to Zero” and “Ignore Lines”, although I am open to suggestions on this one.

- Button “Complete” → This suggests that by pressing the button the inventory will then be done, which on first use makes you reluctant to press it. How about “Update Lines”?

- Button “Count” → I’m not too sure about this button name either, to me it suggests that it will count something. It might be better as “Enter Counts”?

-

Inventory Lines:

- Field: “Quantity” → It seems more natural to call this field “Actual Quantity”, because this is the quantity that is actually there. Commonly, “expected” values will be provided, or plotted on a graph, against “actual” values when showing data.

-

Count Wizard:

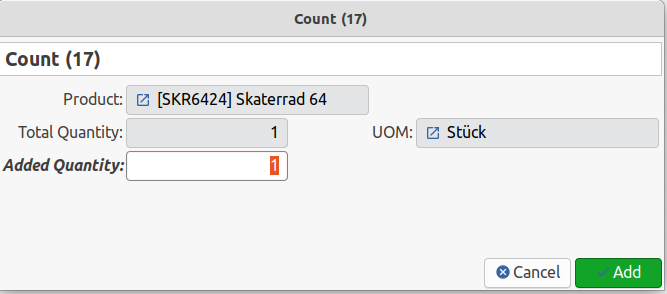

- Field: “Resulting Quantity” → This shows the sum of the inventory line “Quantity” field and the “Added Quantity” field. If many lines for the same product have been entered, then it is the total from all of them, so I suggest it might be better to be called “Total Quantity”.

- Field: “Added Quantity” → I can see how the name of this field has given rise to some misunderstanding, as I don’t think it is immediately clear what this quantity is added to/from. It might be better to just call it “Quantity”.

As far as the error message goes:

I like this suggestion, but maybe it would be better to say “value” instead of “option”? Perhaps:

And, as a final note:

Yes, I think there must also be a gap in my knowledge, as I too fail to understand why 1 is a good default value for this field.