Thankyou @ced and @pokoli for your help. I will describe the general use case in case you can recommend a more optimal solution than the NaN-tic trytond-product_manufacturer module.

In high-tech electronic product manufacturing, especially printed circuit board assemblies, the designer (“engineering”) typically provides a BOM for manufacturing with a purchase specification for each product on the BOM. At a high level, the road to the customer is often an iterative process, starting with product prototype 1, 2, 3… (which are not sold), then an official product release, and later product revision 1, 2, 3… to correct defects and or make product improvements.

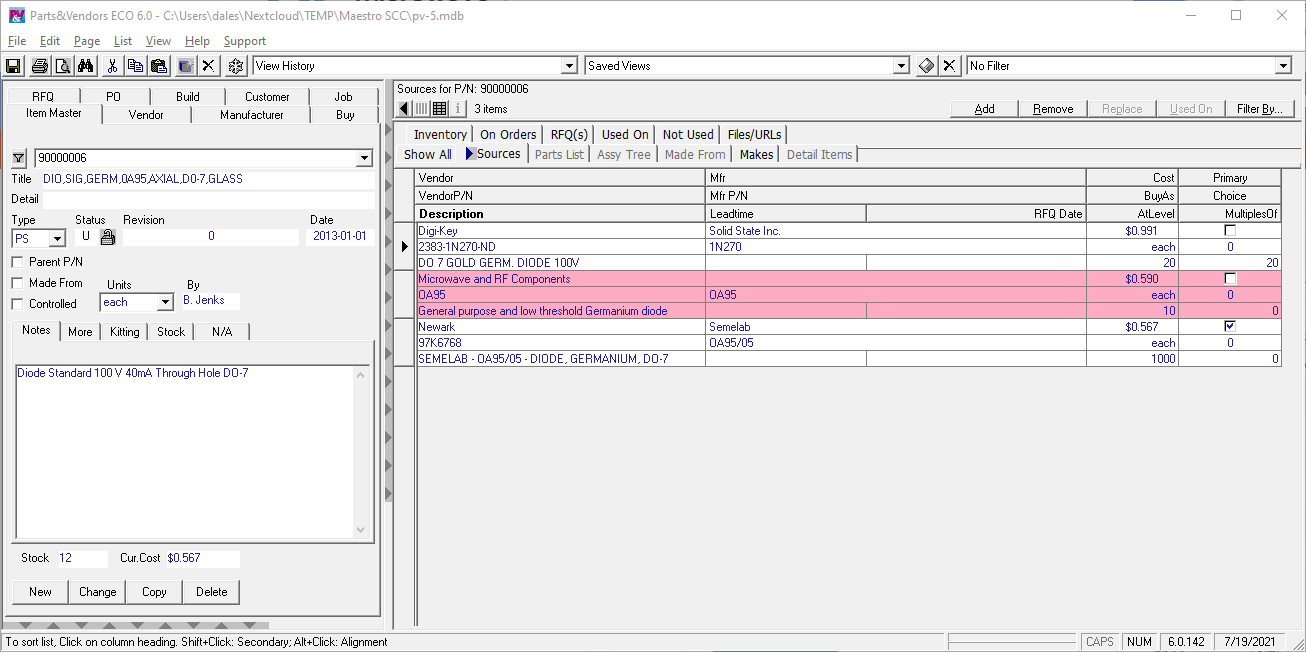

In the electronics industry (and I expect others also), products used as raw materials are typically not purchased from their manufacturer but rather from a distributor or re-seller, and the same part is often available from more than one supplier. Each supplier generally has their own part number for purchasing, and it does not matter which supplier the part is purchased from, so long as the manufacturer’s part number specified by engineering is respected. This provides flexibility in purchasing and reduces support effort needed from engineering.

For example, engineering may specify an STMicroelectronics M74HC04YTTR (a “74HC04”-type hex inverter integrated circuit in a 14-TSSOP package). The purchaser can select the Supplier from avaiale supplies, such as Digi-Key, Arrow, Future, Mouser… based on price, availability, strategic partnership, etc., without going back to engineering for approval.

Although engineering will often initially specify only one source for a particular product on a BOM (e.g. the STM M74HC04YTTR), there can be other manufacturers that make a generally equivalent part (e.g. Texas Instruments CD74HC04MT and ON Semiconductor MM74HC04MTCX). As time passes it is not uncommon for the original source to become unavailable and for engineering to specify additional parts as alternates for purchasing (i.e. the TI and ON Semi parts). Note generally only engineering is qualified to determine if an alternate part is truly alternate though, as very specific characteristics of the design may need to be considered, even to the point of building a special prototype to test and evaluate a potential alternate.

Am I making sense? Generally this is managed by engineering and purchasing in a many-to-many type of table associated with each raw material product, engineering provides Manufacturers and Manufacturer Part Numbers, and purchasing or supply-chain provides Suppliers and Supplier Part Numbers (possibly with approval work flows in the management tool).

Thanks for the help,

Dale