We’ve a customer producing plastic pieces from mold injection (nice GIF) and I found a problem when creating multiple outputs of a BOM, but let me guide you from the real use case so I think it will be more understandable for all fellows that don’t know about the topic.

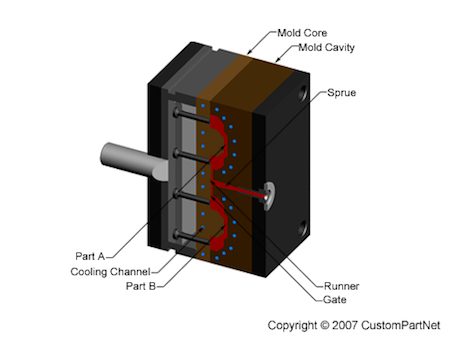

There are some molds that are capable of doing more than one piece in each injection. Like Part A / Part B are connected through a gate, but imagine we can produce much more parts in a single mold:

(img source)

In this image the A and B Part are equal (and go always together, A is the complement of B), so you can make a easy BOM with

bom: 1

mold used: CUSTOMPARTNET

input:

plastic material (10kg)

outputs:

part A (up face) (1u)

part B (down face) (1u)

They can also produce only one of the parts, so they will block the gate that connects A with B so the runner will only go to the not blocked gate.

This become also possible with adding two more BOMs:

bom: 2

mold used: CUSTOMPARTNET

input:

plastic material (5kg)

outputs:

part A (up face) (1u)

bom: 3

mold used: CUSTOMPARTNET

input:

plastic material (5kg)

outputs:

part B (down face) (1u)

So If a costumer buys 10u of part A and 11u of part B, the human logic says that with a production using BOM 1 with quantity 10 will supply 20u of the 21 needed. And another production that can be:

- bom3. quantity = 1 → so we’ll produce the 21º part

- bom1. quantity = 1 → so we’ll produce the 21º part, and have a remaining part A for stock

But, the thing is what if we let the sale_supply_production supply the needs?

I will create 2 productions:

- bom1. quantity = 10, product = part A

- bom1. quantity = 11, product = part B

So if we follow the system we will be consuming nearly the double materials we need and producing the double we need. This is the problem I face.

FTR, I know I can change lead_time to set the “individual” BOM first, but it’s not the best option, as requires more extra time to fill the mold gates manually and the production will be twice as slow (as we will produce 1u/time instead of 2).

Have anyone faced the same or similar scenarios in other industries?